In the ever-evolving manufacturing landscape, the integration of technology is pivotal for optimizing production efficiency and minimizing waste. A recent report by MarketsandMarkets indicates that the global CNC machine market is expected to reach $117.5 billion by 2026, showcasing a robust annual growth rate fueled by advancements in automation and precision technology.

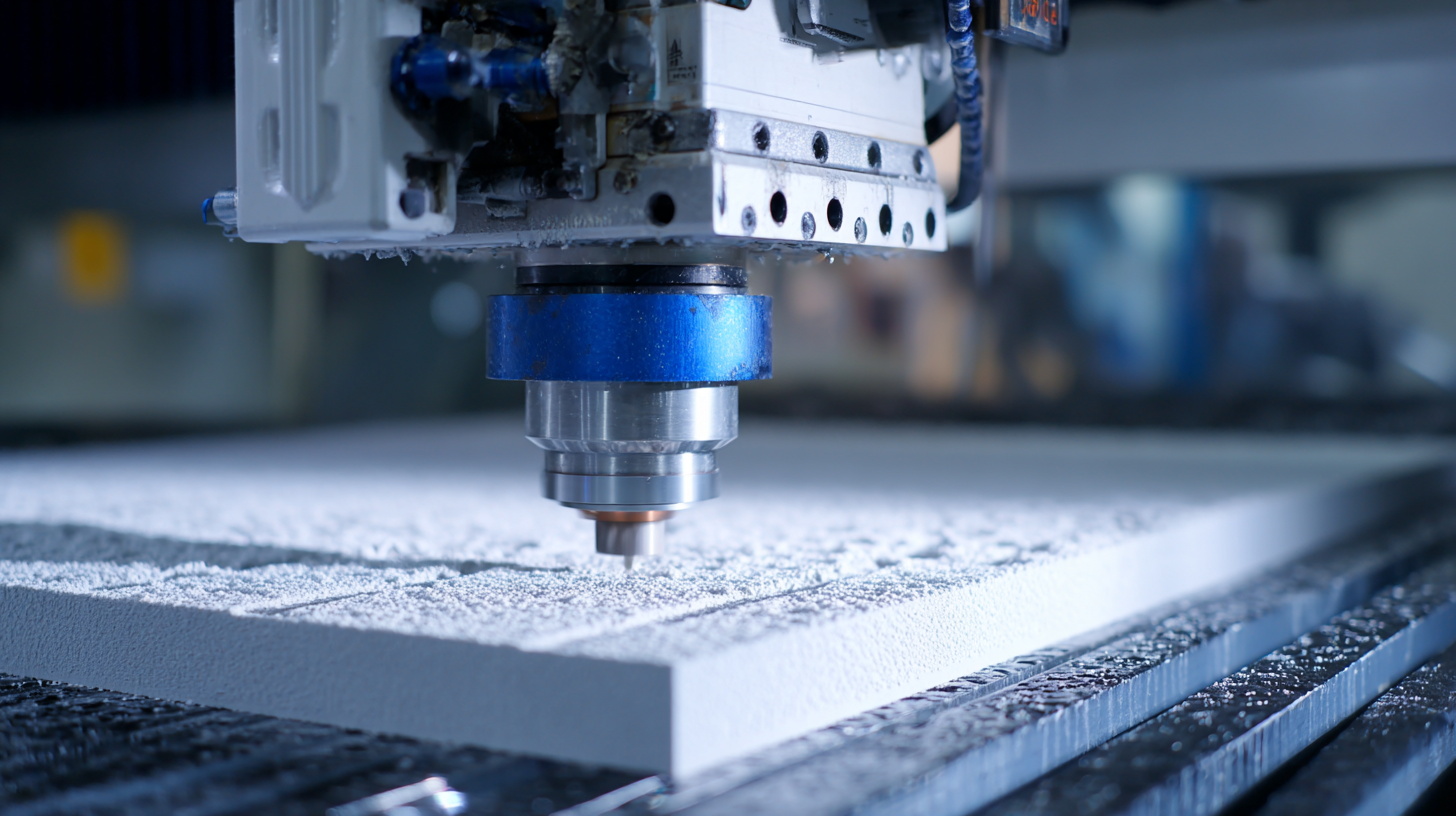

Among these innovations, the foam cutting CNC machine stands out as a transformative tool that enhances productivity while maintaining quality in foam processing industries. By employing a foam cutting CNC machine, manufacturers can achieve intricate designs with minimal material wastage, leading to substantial cost savings and improved operational efficiency. As the demand for customized foam solutions rises, leveraging such cutting-edge technology is not only a competitive advantage but a necessity for companies aiming to stay relevant in the market.

Integrating foam cutting CNC machines into production processes offers a multitude of benefits, particularly in industries such as packaging, automotive, and construction. One significant advantage is the improved precision and consistency these machines provide. According to a report from Technavio, the global CNC machine market is projected to grow by 16.5% between 2020 and 2024, underscoring the increasing reliance on automation and precision in manufacturing. With foam cutting CNC machines, companies can achieve intricate cuts with minimal waste, maximizing material efficiency and reducing costs.

Additionally, foam cutting CNC machines enhance production speed, allowing manufacturers to keep pace with the growing demand for customized products. A study by the International Federation of Robotics highlights that advanced manufacturing technologies, including CNC machines, can reduce production lead times by up to 50%. This capability enables businesses to respond more quickly to customer needs, improving overall satisfaction and competitive advantage. Furthermore, the automation of foam cutting processes can significantly lower labor costs and decrease the risk of human error, making production safer and more economical.

When considering foam cutting CNC machines, knowing the key features can significantly enhance your production process. One of the most important aspects is the cutting precision. High-quality machines should offer accurate cutting capabilities to handle intricate designs and reduce material waste. Look for CNC machines that utilize advanced software, allowing you to input your designs with ease and ensuring consistent results.

Another essential feature is the versatility of the machine. A good foam cutting CNC should be able to handle various foam types and thicknesses. This flexibility allows businesses to cater to different projects without needing separate machines for each foam type. Additionally, examine the machine's speed and efficiency; the faster and more efficient the machine, the better the output and productivity.

Tip: Always consider the maintenance and support options available for the machine. A manufacturer that offers comprehensive support and readily available parts can save you time and costs in the long run. Furthermore, train your staff to maximize the machine's capabilities, as proper usage can lead to significant quality improvements in production.

Setting up a CNC foam cutting system requires careful planning and precision to enhance production efficiency. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach USD 88.5 billion by 2026, indicating a growing trend in automation for various industries. To start, ensure your workspace is organized, allowing for easy access to materials and equipment. This not only boosts productivity but also minimizes downtime.

Setting up a CNC foam cutting system requires careful planning and precision to enhance production efficiency. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach USD 88.5 billion by 2026, indicating a growing trend in automation for various industries. To start, ensure your workspace is organized, allowing for easy access to materials and equipment. This not only boosts productivity but also minimizes downtime.

Tip: Before installation, measure your workspace to choose the appropriate size of the CNC foam cutter that fits without crowding your production area.

Next, you'll need to calibrate your machine for optimal performance. Proper calibration ensures that your cuts are accurate, which is crucial for reducing material waste—a significant cost factor in foam production. A study by the Association for Manufacturing Technology highlights that advanced CNC technology can reduce production costs by up to 20%.

Tip: Regularly update your software and firmware to benefit from the latest features and performance enhancements.

Once your machine is calibrated, train your operators thoroughly. Skilled machine operators are key to maximizing the capabilities of CNC foam cutting systems, as they can execute complex designs with precision, ultimately leading to higher-quality outputs. Thus, invest time in training programs that cover both operation and maintenance of the equipment for long-term success.

In today's fast-evolving manufacturing landscape, optimizing production processes with foam cutting CNC machines has become imperative. The integration of advanced CNC technology not only enhances precision but also accelerates production rates. According to a recent industry report, manufacturers that implement CNC machining can achieve up to a 50% reduction in production time compared to traditional methods. Additionally, enhanced accuracy and consistency in high precision tasks translate into lower material waste, creating a more sustainable operation.

Best practices for the maintenance and operation of CNC machines play a crucial role in maximizing these benefits. Regular maintenance schedules that include checking cutting tools, lubricating moving parts, and ensuring the cleanliness of the machine can significantly reduce downtime. Industry experts suggest that proactive maintenance can increase machine lifespan by up to 30%, while optimized operation techniques, such as effective tool path strategies, can enhance efficiency by as much as 25%. By focusing on these best practices, manufacturers can ensure their CNC machines deliver optimal performance, driving productivity and supporting the transition to automated, environmentally-friendly manufacturing solutions.

In the realm of modern manufacturing, CNC foam cutting machines have emerged as pivotal tools for enhancing production efficiency. Numerous case studies illustrate how companies have harnessed this technology to streamline their operations. One notable example is a furniture manufacturer that integrated CNC foam cutting into its workflow. By automating the cutting process, they significantly minimized material waste and reduced production time, resulting in a 30% increase in output. This optimization not only improved their bottom line but also allowed them to meet customer demands more effectively.

Another compelling case comes from the automotive industry, where a company specializing in custom foam parts utilized CNC cutting technology to refine their production process. By leveraging precise cutting capabilities, they achieved uniformity in their products, which led to improved fit and reduced rework. Additionally, the quick setup and versatility of the CNC machines allowed them to adapt to changing project requirements, positioning them as a market leader in their niche. These success stories highlight the transformative impact of CNC foam cutting, showcasing how strategic investments in technology can lead to substantial operational improvements.