In today's competitive manufacturing landscape, optimizing efficiency is paramount for companies striving to enhance productivity and reduce costs. Advanced turning CNC machines have emerged as critical tools in achieving these goals. According to a recent report by the International Federation of Robotics, the global market for CNC machine tools is projected to reach $100 billion by 2025, with turning CNC machines accounting for a significant share due to their precision and adaptability. Furthermore, studies indicate that integrating advanced CNC technologies can lead to a 30% increase in production speed and a 20% reduction in waste. As manufacturers increasingly leverage turning CNC machines to streamline operations, understanding the key insights and data surrounding their implementation becomes essential for sustained growth and competitiveness in the industry.

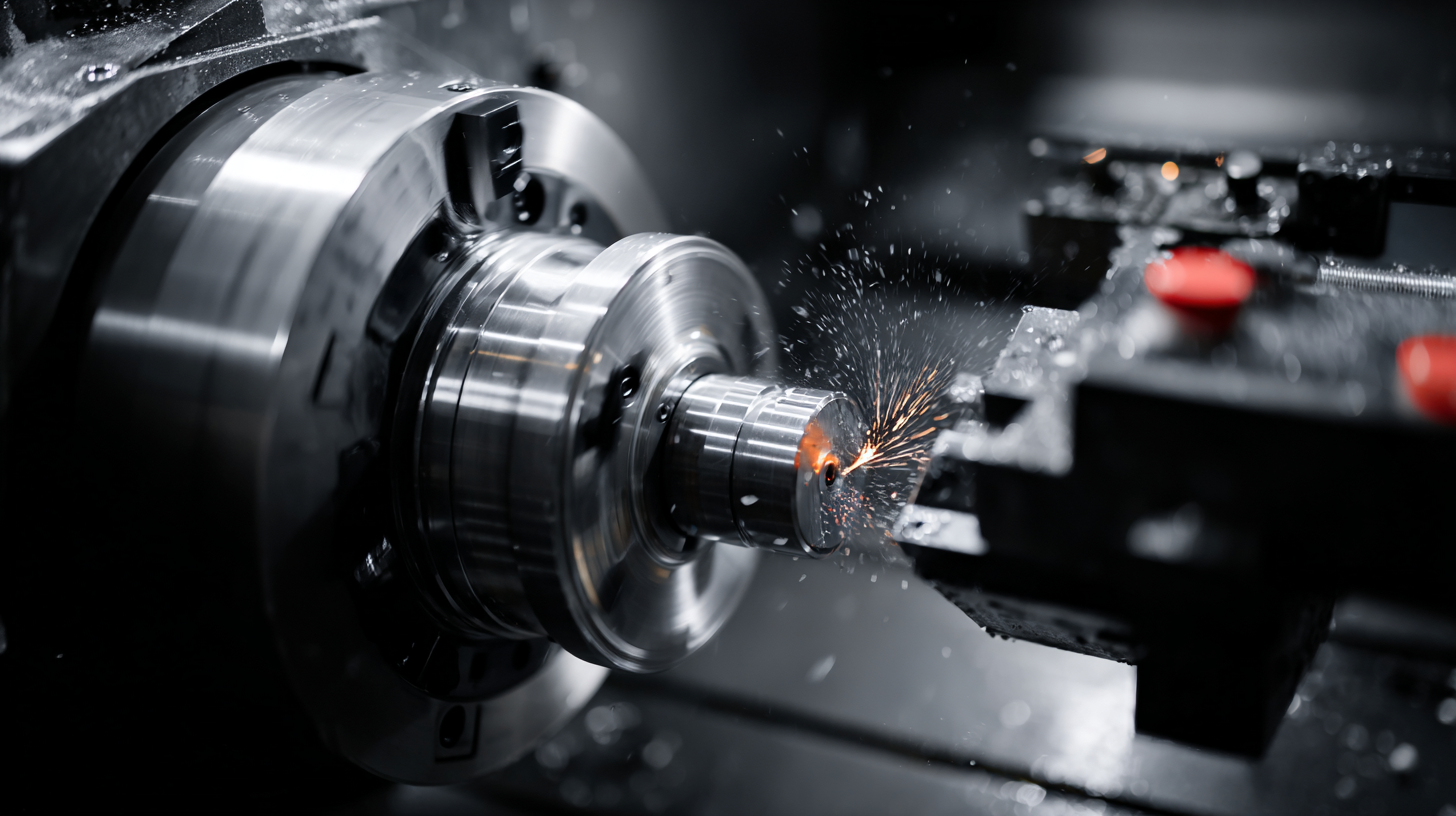

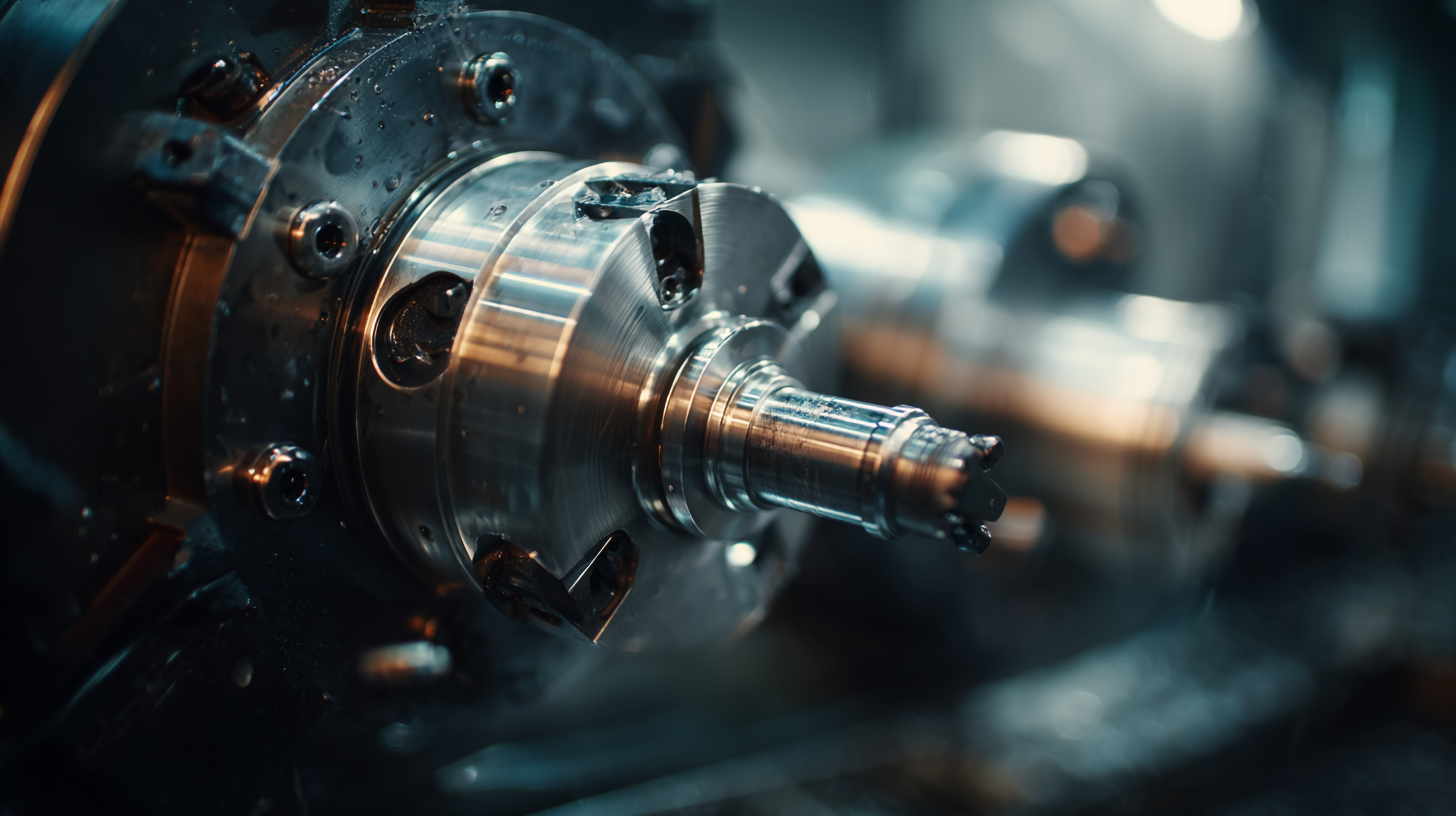

Understanding the basics of turning CNC machines is essential for enhancing manufacturing performance. Turning CNC machines are pivotal in creating precise and consistent parts, making them indispensable in various manufacturing environments. These machines operate by rotating a workpiece against a cutting tool, allowing for intricate shapes and configurations to be formed with high accuracy.

Tip 1: When setting up your turning CNC machine, ensure that the tooling is properly aligned and secured. Misalignment can lead to increased wear on tools and reduced part quality. Regularly checking tool calibration can also help in maintaining optimal efficiency.

The advancements in CNC technology, such as integrated software solutions, can significantly improve efficiency. Utilizing open-source firmware can offer precise control over machine operations, while enhancements in grinding and finishing technologies can further refine the quality of the produced parts.

Tip 2: Incorporate Internet of Things (IoT) solutions into your manufacturing processes. These technologies can provide real-time data on machine performance, enabling better decision-making and quicker responses to potential issues, thus minimizing downtime.

By grasping the fundamental principles of turning CNC machines and leveraging modern advancements, manufacturers can achieve improved efficiency and product quality across their operations.

Advanced turning CNC machines are pivotal in enhancing manufacturing efficiency. One of the key features that contribute to this efficiency is their precision. These machines utilize advanced algorithms and sensors to maintain tight tolerances, reducing waste and the need for manual adjustments. This precision not only streamlines the production process but also ensures higher quality output, minimizing the risks associated with defects.

Advanced turning CNC machines are pivotal in enhancing manufacturing efficiency. One of the key features that contribute to this efficiency is their precision. These machines utilize advanced algorithms and sensors to maintain tight tolerances, reducing waste and the need for manual adjustments. This precision not only streamlines the production process but also ensures higher quality output, minimizing the risks associated with defects.

Another significant feature is automation capabilities. Advanced turning CNC machines can operate autonomously, allowing for longer production runs without human intervention. This automation not only frees up valuable labor resources but also supports continuous operation, which can dramatically increase overall output. Integrating these machines with smart factory technologies further enhances their ability to optimize workflows.

Tips: When considering the implementation of advanced turning CNC machines in your production line, focus on training your team on the specific software and tools used in these machines. Additionally, regularly maintaining and calibrating your equipment will ensure sustained efficiency and minimize downtime. Lastly, analyze production data to identify bottlenecks and continuously refine your processes for optimal performance.

Integrating CNC technology into existing manufacturing processes is essential for enterprises aiming to optimize efficiency and productivity. One of the best practices is to ensure that the CNC systems are compatible with existing operations, allowing for seamless data exchange between operational technology (OT) and information technology (IT). This integration facilitates real-time monitoring and enhances decision-making capabilities across the production floor, ultimately leading to a more agile manufacturing environment.

Moreover, companies should consider adopting advanced CNC solutions that prioritize sustainability and energy efficiency. By transitioning to machines that reduce waste and improve precision, businesses can not only cut operational costs but also align with environmental standards. As the industry moves toward Industry 4.0, leveraging digital technologies such as data analytics and IoT can further enhance the capabilities of CNC systems, enabling manufacturers to adapt to changing market demands swiftly. Investing in training for personnel to effectively use and maintain these technologies is equally crucial in maximizing their full potential.

In the realm of CNC operations, analyzing production data is essential for uncovering inefficiencies and optimizing workflows. By leveraging advanced analytical tools, manufacturers can track key performance indicators (KPIs) such as cycle times, machine utilization, and tool wear rates. These metrics provide insight into operational bottlenecks that may not be apparent through traditional observation methods. For instance, if data reveals consistently longer cycle times on specific machines, it may indicate the need for preventive maintenance or operator training to enhance proficiency.

Moreover, integrating real-time data analytics allows for continuous monitoring of the production process, enabling manufacturers to make swift, informed decisions. By employing techniques such as predictive analytics, organizations can forecast potential downtime or identify when tools require replacement, thus minimizing disruptions. The implementation of data-driven strategies fosters an environment of continuous improvement, where adjustments based on empirical evidence lead to increased efficiency and reduced costs in manufacturing operations. Advanced turning CNC machines, when paired with robust data analysis, can transform production processes, ensuring that manufacturers remain competitive in today’s fast-paced market.

To truly maximize the efficiency of advanced turning CNC machines, investing in training and skill development for operators is paramount. A study by the National Institute of Standards and Technology (NIST) indicates that companies with well-trained operators can improve their manufacturing productivity by up to 20%. This improvement is often attributed to increased machine utilization and reduced error rates. By providing in-depth training programs, manufacturers equip their workforce with the necessary skills to operate these sophisticated machines effectively, leading to smoother operations and enhanced output.

To truly maximize the efficiency of advanced turning CNC machines, investing in training and skill development for operators is paramount. A study by the National Institute of Standards and Technology (NIST) indicates that companies with well-trained operators can improve their manufacturing productivity by up to 20%. This improvement is often attributed to increased machine utilization and reduced error rates. By providing in-depth training programs, manufacturers equip their workforce with the necessary skills to operate these sophisticated machines effectively, leading to smoother operations and enhanced output.

Tips for Effective Training:

1. Implement hands-on workshops that allow operators to familiarize themselves with the latest CNC technology and software.

2. Encourage a culture of continuous learning, where operators can regularly update their skills and knowledge through industry courses and certifications.

Furthermore, data from the Manufacturing Institute reveals that investing in operator training can lead to a reduction in downtime by as much as 30%. This reduction can be achieved by minimizing the time spent troubleshooting problems caused by operator errors. Regular assessments and refresher courses help operators stay current with new machine technologies and techniques, ensuring that they can utilize these machines to their fullest potential.