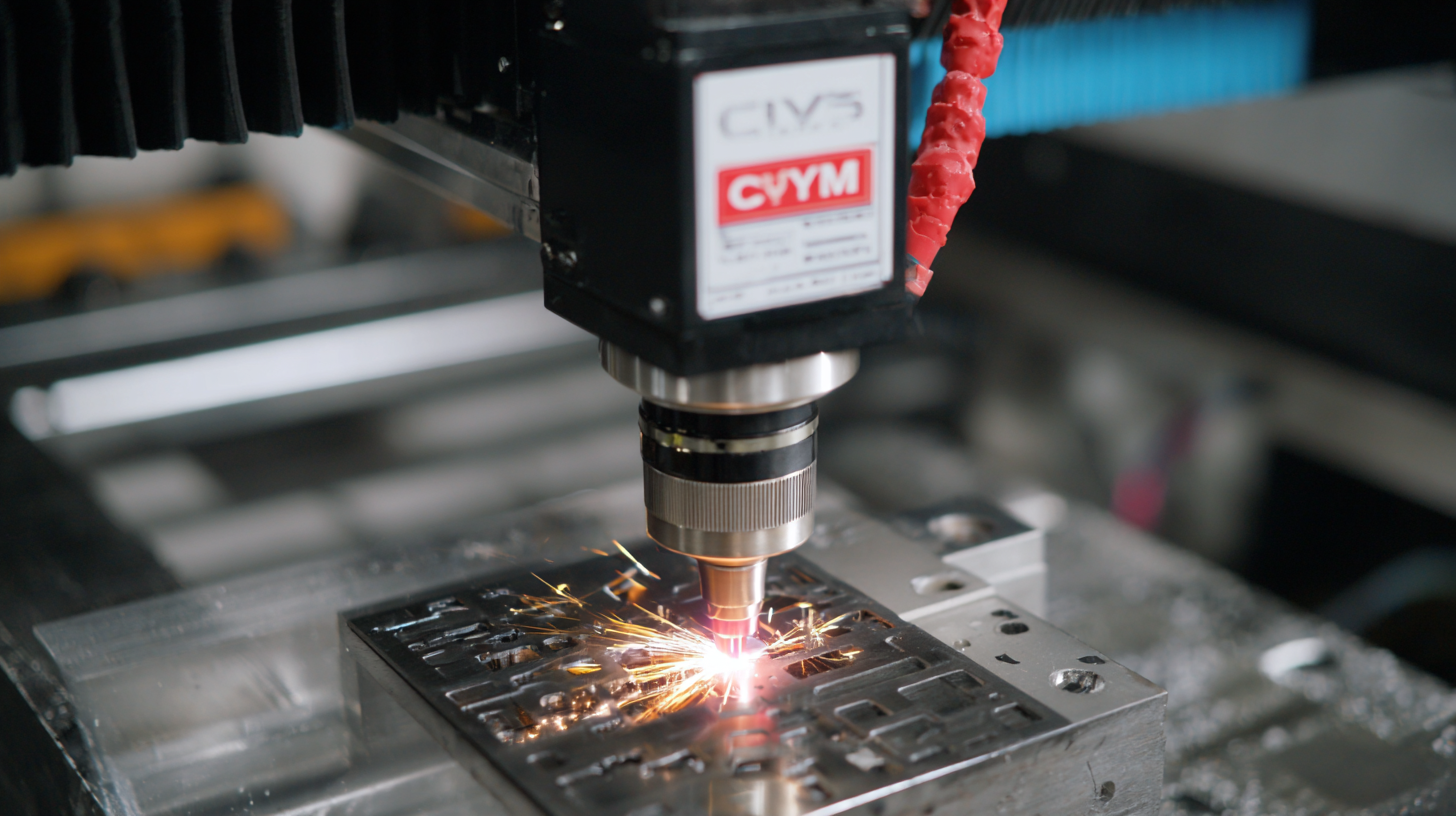

In the rapidly evolving landscape of manufacturing, the adoption of advanced technologies such as the laser cutting CNC machine has become increasingly vital for businesses striving to enhance productivity and precision. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach USD 5.56 billion by 2025, demonstrating a compound annual growth rate (CAGR) of 6.2%. This surge is fueled by the growing demand for high-quality cutting solutions that offer intricate design capabilities and reduced fabrication times. Laser cutting CNC machines provide unparalleled benefits, including minimal material waste, the ability to cut complex shapes with high accuracy, and the versatility to work with a wide range of materials. As industries continue to seek innovative solutions to meet production demands, understanding how to effectively select the right laser cutting CNC machine tailored to specific operational needs is imperative for maintaining a competitive edge.

When considering the selection of a laser cutting CNC machine for global markets, several critical factors must be evaluated. First, understanding the projected growth of the CNC machine market, which is expected to expand significantly from $101.22 billion in 2025 to $195.59 billion by 2032, can influence purchasing decisions. As industries increasingly adopt automation and precision cutting technologies, the demand for high-quality laser cutting machines rises, making it essential to align your investment with market trends.

Additionally, you should assess the specific applications your machine will serve. Different industries require different capabilities—whether for metal machining, sheet metal processing, or specialized tube cutting. The growth in sectors like oil and gas emphasizes the importance of selecting a machine that not only meets immediate production needs but is also adaptable for future expansions. As competition in the global market heightens, choosing the right laser cutting CNC machine can significantly enhance operational efficiency and product quality.

Understanding these factors will empower businesses to make informed decisions that support long-term success in a fast-evolving market landscape.

When selecting a laser cutting CNC machine, it's crucial to understand the various types of laser cutting technologies available and their specific applications. The three most common laser types are CO2 lasers, fiber lasers, and solid-state lasers. CO2 lasers are widely used for cutting non-metal materials such as wood, plastic, and glass, making them an excellent choice for industries like signage and packaging. They offer a high-quality cut at a relatively low operational cost, which is why many businesses opt for them.

On the other hand, fiber lasers excel in cutting metal materials and are known for their efficiency and speed. They can process various metals, including stainless steel, aluminum, and brass, making them particularly suitable for the automotive and aerospace industries. Moreover, fiber lasers are more energy-efficient than CO2 lasers and require less maintenance, leading to lower long-term operating costs. Understanding these differences can guide manufacturers in selecting the right technology for their production needs, ultimately boosting productivity and reducing waste.

Evaluating the quality standards of Chinese laser cutting machines for international trade is essential as the global market becomes increasingly competitive. According to a report by Markets and Markets, the global laser cutting machine market is expected to reach USD 5.6 billion by 2025, with a significant contribution from Chinese manufacturers who dominate approximately 40% of the world's supply. This statistic highlights the growing reliance on Chinese technology, thus placing a premium on understanding the quality benchmarks these machines must meet.

China’s laser cutting industry is subject to various quality certifications, including ISO 9001 for quality management systems and CE marking for compliance with European safety standards. A 2022 study by the China Machine Tool Industry Association indicated that 60% of laser cutting machine manufacturers in China have received international certifications, ensuring their products meet rigorous safety and performance criteria. As international buyers seek reliable machinery, understanding these quality standards can greatly influence purchasing decisions, ensuring that businesses invest in equipment that not only meets their production needs but also aligns with international regulations and standards.

| Machine Model | Max Cutting Thickness (mm) | Laser Power (W) | Cutting Speed (m/min) | Accuracy (mm) | Operating Voltage (V) |

|---|---|---|---|---|---|

| Model A | 20 | 1000 | 30 | 0.05 | 220 |

| Model B | 25 | 1500 | 35 | 0.04 | 380 |

| Model C | 15 | 500 | 25 | 0.06 | 220 |

| Model D | 30 | 2000 | 45 | 0.03 | 380 |

When assessing the cost-effectiveness of laser cutting CNC machines for your business, it's crucial to consider both the initial investment and long-term operational expenses. Laser cutting technology offers precision and efficiency, which can significantly reduce production time and material waste. By analyzing the machine’s energy consumption, maintenance requirements, and the cost of consumables like laser tubes, businesses can develop a clearer picture of the overall financial commitment.

Additionally, comparing the capabilities of various laser cutting CNC machines in terms of versatility and speed is essential. A machine that not only meets current production needs but also has the potential to handle diverse projects can lead to more significant cost savings over time. As the plasma cutting machine market projects notable growth, investing in advanced laser cutting technology is becoming increasingly advantageous for modern manufacturers aiming to stay competitive while minimizing their environmental impact through sustainable practices.

When sourcing laser cutting machines, particularly from China, it's crucial to identify reliable suppliers to ensure quality and performance. According to a report from ResearchAndMarkets, the global laser cutting machine market is projected to reach $6.5 billion by 2026, with significant contributions from Chinese manufacturers that account for over 30% of this growth. This indicates a strong presence of competitive suppliers capable of providing advanced technology and cost-effective solutions.

To effectively navigate the sourcing process, buyers should focus on several key factors. Firstly, conducting thorough background checks on suppliers is essential. Look for companies with ISO certifications or those that have been recognized by industry standards to ensure that they meet international quality benchmarks. Additionally, leveraging platforms like Alibaba or Made-in-China can simplify the search, but it’s vital to prioritize suppliers with strong customer reviews and verified ratings. According to the International Federation of Robotics, over 60% of purchasing decisions are influenced by positive customer feedback, highlighting the importance of assessing supplier reputations.

Furthermore, requesting detailed specifications and performance data of their laser cutting machines can aid in making informed decisions. An industry analysis by Market Research Future indicates that efficiency improvements in laser cutting technologies can lead to reductions in production costs by up to 20%. This aspect is crucial for manufacturers aiming to optimize their production processes while ensuring they source from reliable suppliers.