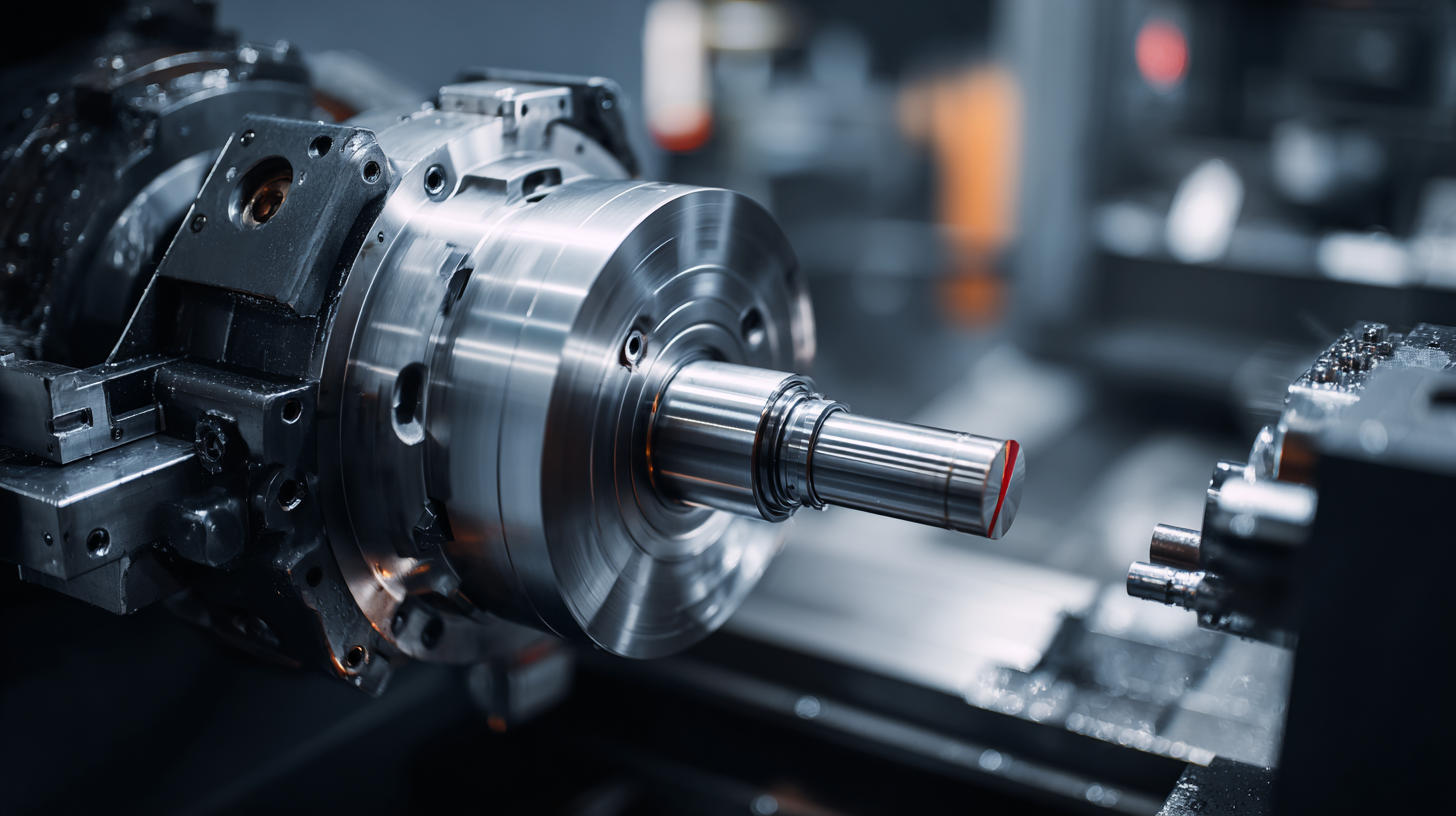

In the rapidly evolving landscape of manufacturing, navigating global trade certifications is crucial for businesses aiming to procure the best industrial CNC machines. With the global CNC machine market projected to reach approximately $100 billion by 2026, driven by advancements in automation and precision engineering, understanding certification requirements becomes imperative for industry professionals. These certifications not only ensure compliance with international quality standards but also enhance operational efficiency and competitiveness in a crowded market. For instance, the implementation of ISO 9001 standards has been shown to improve product quality and customer satisfaction by up to 20%. As companies strive to optimize their production processes and adapt to fluctuating global demands, familiarizing oneself with the essential certifications for industrial CNC machines is key to unlocking their full potential and achieving sustainable growth.

In the realm of CNC machining, understanding global trade certifications is essential for manufacturers aiming to ensure product quality and compliance with international standards. These certifications act as a testament to a machine's reliability, safety, and performance, allowing companies to bolster their credibility in diverse markets. For instance, certifications such as ISO 9001 and CE mark signify commitment to quality management systems and adherence to European safety standards, respectively. This assures customers that the machines they are investing in meet rigorous industry benchmarks.

Furthermore, global trade certifications can facilitate smoother entry into international markets by simplifying customs processes and reducing regulatory hurdles. They not only enhance the competitive positioning of CNC machine manufacturers but also build trust with potential clients. In an increasingly interconnected world, where consumer preferences lean towards reliable and ethically produced machinery, having recognized certifications can play a pivotal role in business success. As manufacturers navigate the complexities of exports and imports, prioritizing these certifications can lead to sustainable growth and expanded market opportunities.

When it comes to CNC manufacturing, adhering to key industry standards such as ISO and CE is paramount for ensuring quality and safety. ISO (International Organization for Standardization) certifications establish guidelines that promote efficiency and quality control within operational processes. According to a report by the International Trade Centre, companies that adhere to ISO standards can experience up to a 20% reduction in operational costs. On the other hand, CE marking signifies conformity with health, safety, and environmental protection standards for products offered within the European Economic Area. It not only enhances product credibility but also broadens market access, a critical factor in an increasingly globalized economy.

When it comes to CNC manufacturing, adhering to key industry standards such as ISO and CE is paramount for ensuring quality and safety. ISO (International Organization for Standardization) certifications establish guidelines that promote efficiency and quality control within operational processes. According to a report by the International Trade Centre, companies that adhere to ISO standards can experience up to a 20% reduction in operational costs. On the other hand, CE marking signifies conformity with health, safety, and environmental protection standards for products offered within the European Economic Area. It not only enhances product credibility but also broadens market access, a critical factor in an increasingly globalized economy.

Tips: When selecting a CNC machine, ensure that it complies with relevant ISO standards to guarantee reliable performance. Additionally, pay attention to whether the machine has a CE mark, which can ease regulatory burdens in foreign markets.

CNC manufacturers must also be aware of the significance of these certifications in establishing trust with clients. A study conducted by the European Commission highlighted that 70% of consumers prioritize product compliance with safety standards when making purchasing decisions. Thus, obtaining ISO and CE certifications is not just about regulatory compliance; it's essential for fostering customer confidence and securing competitive advantages in the market.

Tips: Leverage certifications in your marketing strategy to build trust with potential clients, emphasizing your commitment to quality and safety in CNC manufacturing.

When assessing CNC machines for industrial applications in 2023, understanding the various certifications can significantly influence purchasing decisions. Key certifications include ISO 9001 for quality management, CE marking for compliance with European safety standards, and UL certification for electrical safety. A report from MarketsandMarkets cites that the global CNC machine market is expected to reach $117.8 billion by 2026, underscoring the critical role that certified machines play in ensuring operational efficiency and safety in competitive manufacturing environments.

Moreover, certifications such as the AS9100, primarily relevant in aerospace, and the ISO 13485 for medical devices, are increasingly gaining importance as industries emphasize quality and regulatory compliance. According to a study by Statista, over 70% of manufacturers now prioritize purchasing certified machines, driven by consumer demand for quality assurance and regulatory adherence. As companies strive to improve productivity and reduce downtime, investing in certified CNC machines is not just a regulatory consideration but a strategic move that enhances brand reputation and operational resilience.

In today’s rapidly evolving manufacturing landscape, ensuring that your CNC machines comply with global standards is essential for competitive success. Compliance not only enhances the safety and reliability of your equipment but also broadens market access and boosts your brand's credibility. The first step in this process is to thoroughly understand the specific regulations and standards pertinent to your industry and target markets, such as ISO certifications, CE marking in Europe, or ANSI standards in the United States. Familiarizing yourself with these requirements will help you determine the qualifications necessary for your machines and identify any potential gaps in compliance.

Once you have a clear understanding of the regulations, the next step is to implement a robust compliance strategy. This may involve consulting with experts or accreditation bodies, conducting regular audits, and ensuring that your production processes align with the necessary standards. It’s crucial to document all compliance measures and maintain clear records of all certifications achieved. Additionally, collaborating with suppliers and manufacturers who themselves are compliant can streamline the process, reducing risks associated with non-compliance. By prioritizing these steps, businesses can navigate the complex landscape of global trade certifications and position their CNC machines for success in international markets.

The landscape of CNC certification is experiencing a significant transformation as we approach 2025, a year projected to be pivotal for industrial automation. The global CNC machine market is expected to surge from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, growing at a CAGR of 9.9%. This upward trajectory signals an increasing demand for precision and performance in manufacturing, driven by innovations in design and technology. As CNC machining integrates more with automation and AI, the certifications relevant to these technologies will likewise need to evolve, ensuring that operators are equipped with the latest skills and knowledge.

**Tips:** Focus on emerging trends in machine learning and AI integration when considering certification options. Understanding the implications of these technologies will enhance your skill set and marketability. Additionally, companies should keep abreast of international standards to ensure compliance and remain competitive in the global market.

With China emerging as a key player in advanced manufacturing, its innovations are likely to shape the future of CNC certification. Emphasizing sustainable practices and technological advancements, organizations must adapt to this rapidly changing environment. Embracing new methodologies will not only align with global trends but also position businesses favorably amidst the anticipated growth of industrial automation.

**Tips:** When navigating certification programs, consider those that offer insights into AI and robotics, as they will be integral to future CNC operations. Investing in continual learning is essential to harness the full potential of evolving CNC technologies.