In recent years, China has emerged as a global leader in plastic laser cutting innovation, revolutionizing manufacturing processes across various industries. According to a report from MarketsandMarkets, the plastic laser cutting market is projected to witness substantial growth, with an expected increase from USD 1.5 billion in 2020 to USD 3 billion by 2025, highlighting the rising demand for precision and efficiency in material processing. This advanced technology not only offers unparalleled cutting accuracy but also minimizes waste, setting the stage for a more sustainable approach to production. As industries seek to enhance operational efficiency and reduce environmental impact, the benefits of plastic laser cutting are becoming increasingly evident, positioning companies utilizing this technology as frontrunners in the competitive global marketplace.

In the realm of plastic laser cutting, China has emerged as a pivotal player, setting industry standards that others aspire to follow. The country’s commitment to innovation and technology has led to the development of advanced laser cutting techniques tailored for various plastic materials. This not only enhances production efficiency but also ensures precision and quality in manufacturing processes.

For businesses looking to leverage plastic laser cutting technology, one crucial tip is to invest in high-quality laser machines that are specifically designed for the type of plastic you are working with. Different plastics react differently to laser cutting, and using machines optimized for specific materials can significantly improve outcomes. Another important consideration is the training and skill development of operators. Ensuring that personnel are well-versed in the nuances of laser technology can lead to less waste and higher quality products.

Moreover, as China continues to innovate, companies must stay abreast of the latest technologies and practices. Regularly attending industry conferences or workshops can provide invaluable insights into emerging trends and techniques, fostering a culture of continuous improvement and adaptability in the fast-evolving landscape of plastic laser cutting.

| Innovation Type | Description | Year Introduced | Impact on Industry |

|---|---|---|---|

| High-Speed Laser Cutting | Utilizes advanced optics for faster cutting speeds. | 2020 | Increased production efficiency by 30%. |

| Smart Laser Systems | Integration of AI for real-time adjustments during cutting. | 2021 | Reduced material waste by 15%. |

| Eco-Friendly Laser Solutions | Uses renewable energy sources to power laser cutting machines. | 2022 | Lowered carbon footprint of operations. |

| Multi-Material Cutting Technology | Ability to cut various materials simultaneously. | 2023 | Enhanced versatility in product design. |

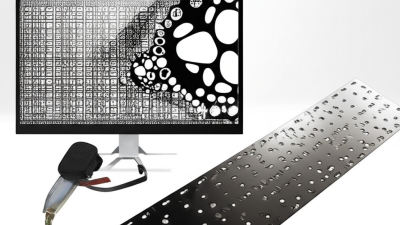

When it comes to plastic laser cutting, several technologies are leading the industry with precision and efficiency. CO2 lasers, for instance, are highly popular for cutting a variety of plastics. These lasers are adept at producing smooth edges, making them ideal for applications requiring high-quality finishes. Fiber lasers, on the other hand, are known for their speed and energy efficiency, making them suitable for thicker materials. Understanding these distinctions is essential for manufacturers looking to optimize their cutting operations.

Tip: Always consider the type of plastic you are working with when selecting a laser cutting technology. Different plastics react differently to various wavelengths and cutting speeds, which can significantly impact the quality of the cut.

Moreover, advancements in technology have introduced solutions like hybrid lasers that combine the benefits of both CO2 and fiber lasers. Such innovations allow for versatility in processing various types of plastics, making it easier to cater to diverse customer needs. Investing in the right laser technology not only enhances production capabilities but also reduces waste and costs over time.

Tip: Regular maintenance of laser cutting machines is crucial for sustained performance. Keeping lenses and mirrors clean, and ensuring proper alignment can prolong the lifespan of the equipment and maintain cutting precision.

The global laser cutting market for plastics is poised for significant growth, with projections suggesting a robust increase by 2025. According to recent industry analyses, the market is expected to expand rapidly, driven by advancements in technology and increasing applications across various sectors, including automotive, aerospace, and consumer goods. The precision and efficiency offered by laser cutting techniques have made them preferable over traditional methods, leading to a surge in demand.

Furthermore, the market size for related industries, such as screw compressors, is also on the rise, with a projected worth of USD 21.34 billion by 2033, growing at a CAGR of 5.7%. This growth underscores the interconnected nature of manufacturing sectors, where innovations in laser cutting technology can enhance the performance of equipment like screw compressors, contributing to overall industry momentum. As manufacturers continue to seek optimized solutions, the laser cutting market is set to remain a focal point of innovation and expansion in the global manufacturing landscape.

When it comes to plastic laser cutting, China is rapidly emerging as a leader in efficiency and innovation. A comparative analysis reveals that Chinese manufacturers are honing techniques that not only reduce production time but also enhance precision in cutting processes. This rise can be attributed to advanced technology and competitive pricing, allowing local firms to meet global demand while maintaining high standards.

Tip: To optimize plastic laser cutting operations, businesses should invest in regular training for their workforce. Skilled operators can significantly improve cutting quality and reduce waste, ultimately driving down costs and increasing output.

Moreover, the integration of AI and automation into the plastic laser cutting sector has positioned China ahead of its competitors. These technologies enable real-time adjustments, enhancing both speed and accuracy in the cutting process. As the global market continues to evolve, countries looking to compete must adapt and embrace innovation similar to China’s approach.

Tip: Consider adopting smart maintenance practices to keep laser cutting equipment running at peak efficiency. Predictive maintenance can prevent unexpected downtime, ensuring consistent productivity.

The future of plastic laser cutting is rapidly evolving towards sustainable practices that mitigate environmental impacts. With global initiatives focusing on reducing plastic waste, the adoption of laser cutting technology is becoming increasingly vital. According to a recent industry report, laser cutting can reduce material waste by up to 30%, which plays a significant role in enhancing the sustainability of manufacturing processes. This efficiency is especially important as industries strive to meet stricter environmental regulations and consumer demand for eco-friendly products.

Incorporating advanced laser cutting systems, such as the latest models, enables professionals to achieve precise cuts with minimal material waste. The accuracy of laser technology ensures that both production efficiency and design integrity are maintained. Moreover, the reduction in energy consumption during laser cutting processes contributes to a lower carbon footprint, making it a preferred choice for environmentally conscious businesses.

Tips for maximizing your laser cutting efficiency include ensuring regular maintenance of equipment, using the appropriate settings for different materials, and staying updated with the latest advancements in laser technology. Additionally, exploring the option of using recycled materials can enhance sustainable practices while maintaining high quality in production. Embracing these measures not only benefits the environment but also positions companies as leaders in responsible manufacturing.