In the ever-evolving landscape of global manufacturing, the quest for precision, efficiency, and innovation has never been more critical. At the forefront of this transformation are industrial CNC laser cutting machines, which epitomize cutting-edge technology and superior craftsmanship. Made in China, these machines not only boost productivity but also elevate manufacturing standards worldwide. As industries face increasing demands for high-quality cuts and intricate designs, the benefits of adopting advanced laser cutting technology become undeniable. This blog will explore how the best industrial CNC laser cutting machines from China are setting new benchmarks in manufacturing, driving competitiveness, and enabling businesses to meet the challenges of a dynamic market environment. Join us as we delve into the transformative power of these machines and their pivotal role in shaping the future of global manufacturing.

The competitive edge of Chinese CNC laser cutting machines in the global market cannot be overstated. As the world grapples with a booming CNC machinery market, projected to reach over $195 billion by 2032, China's manufacturers are at the forefront, innovating and enhancing technology to meet international standards. The rapid growth of the laser cutting machines market, anticipated to experience a CAGR of 9.9%, highlights how Chinese firms have adapted to global demands by investing in advanced technologies. These companies leverage cost-effective production while maintaining quality, allowing them to offer competitive pricing without compromising on performance.

Moreover, as China strives for self-reliance in technology, its CNC laser cutting machines have become synonymous with precision and efficiency. While challenges remain, such as competition in high-end machine tools, the momentum of technological advancement positions Chinese manufacturers as vital players in shaping industry standards worldwide. The laser cutting segment, in particular, is witnessing significant transformation, driven by innovations that are setting new benchmarks for manufacturing excellence. This dynamic environment showcases not only China's ability to compete but also its role as a leading innovator in the global industrial landscape.

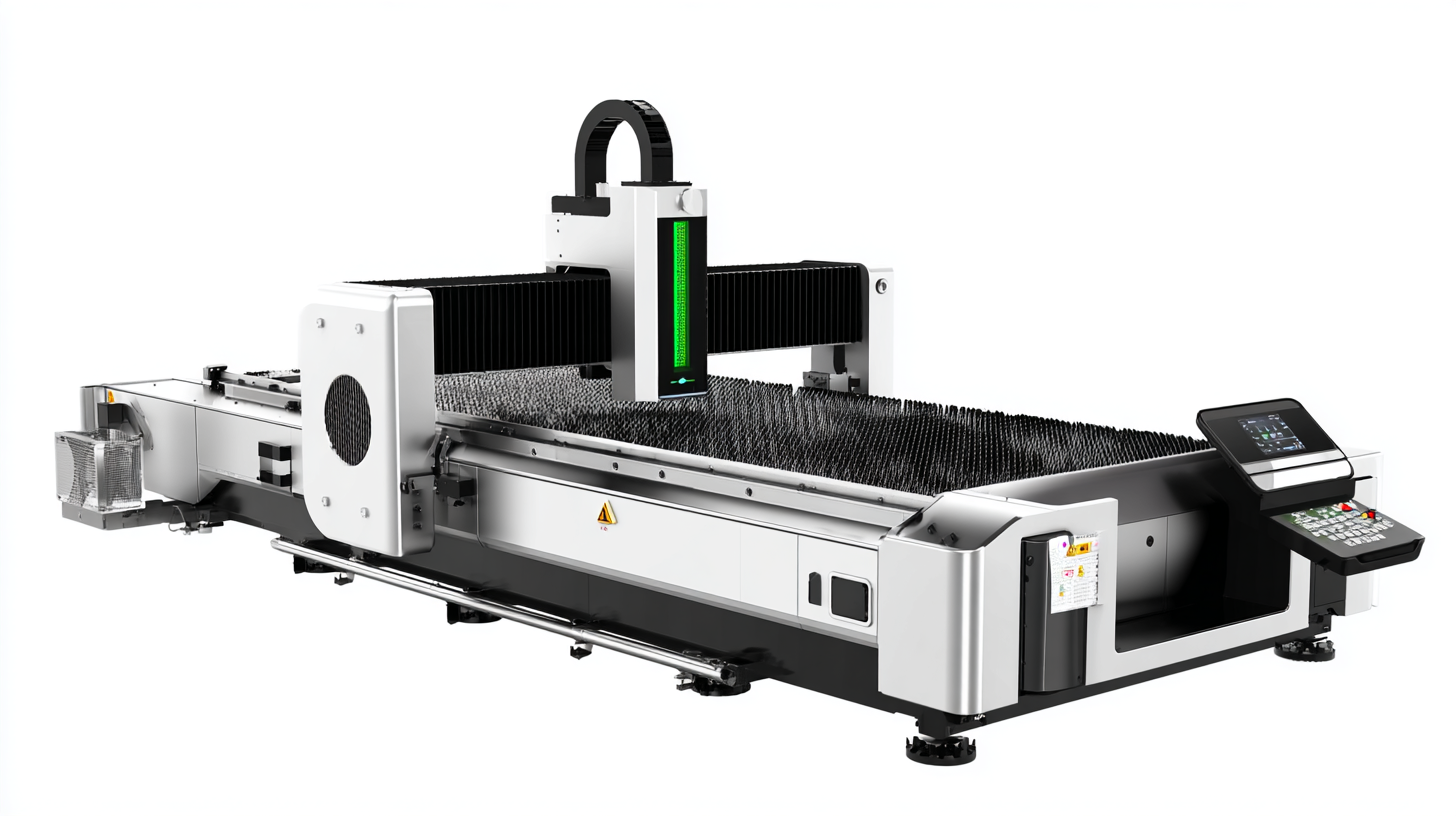

In the competitive landscape of industrial manufacturing, the integration of innovative technology plays a pivotal role in driving efficiency and productivity. The advent of advanced CNC laser cutting machines, particularly those manufactured in China, exemplifies how cutting-edge technology can revolutionize traditional manufacturing processes. These machines utilize high-precision laser technology that not only enhances the accuracy of cuts but also significantly reduces material wastage. This efficiency ensures that manufacturers can optimize their operations while simultaneously decreasing costs, making it a win-win situation.

Moreover, the relentless pursuit of innovation in CNC laser cutting technology fosters continuous improvements in manufacturing standards globally. With features like automated control systems, real-time data monitoring, and user-friendly interfaces, these machines empower manufacturers to meet the demands of an ever-evolving market. The combination of high-speed cutting capabilities and versatility allows for intricate designs and customization, which are increasingly important in today’s consumer-driven economy. As the industry embraces these advancements, it sets a benchmark for quality and performance that elevates global manufacturing standards to new heights.

| Machine Model | Laser Power (W) | Max Cutting Thickness (mm) | Cutting Speed (m/min) | Precision (mm) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 1000 | 18 | 25 | 0.05 | 800 |

| Model B | 1500 | 20 | 30 | 0.04 | 900 |

| Model C | 2000 | 25 | 35 | 0.03 | 1000 |

In the competitive landscape of global manufacturing, the assurance of quality in CNC machine production is paramount. Chinese manufacturers have made significant strides in quality assurance practices, particularly through the implementation of advanced technologies such as the touch probing system. This system enables automatic data collection, thereby enhancing the precision and reliability of CNC machining processes. By utilizing real-time data, manufacturers can continuously monitor and optimize their operations, leading to elevated standards in machining efficiency and product quality.

Moreover, the integration of cutting-edge tools in the CNC machine fabrication process underscores China's commitment to excellence in manufacturing. Emphasizing a culture of continuous improvement, practices like systematic research to optimize milling parameters highlight the proactive approach taken by these manufacturers. As they adapt to the evolving demands of the market, the focus on robust quality assurance measures ensures that products meet or exceed international standards, positioning Chinese-made CNC machines at the forefront of the industry.

The sustainability and environmental impact of advanced laser cutting solutions play a crucial role in the modern manufacturing landscape. According to a report by Markets and Markets, the global laser cutting market is expected to reach $7.5 billion by 2026, driven by the increasing demand for energy efficiency and waste reduction. CNC laser cutting machines, particularly those manufactured in China, are designed to optimize material use and minimize energy consumption, significantly lowering the carbon footprint associated with traditional cutting methods.

Incorporating factors such as precision and speed, advanced laser cutting technologies not only enhance productivity but also promote eco-friendliness. A study from the International Journal of Advanced Manufacturing Technology highlights that laser cutting generates up to 80% less waste compared to conventional cutting techniques. Moreover, these machines often utilize clean energy sources, resulting in a substantial decrease in greenhouse gas emissions. As manufacturers increasingly embrace these technologies, the transition towards sustainable production practices becomes more achievable, reflecting a collective commitment to reducing environmental impact in the industrial sector.

Incorporating factors such as precision and speed, advanced laser cutting technologies not only enhance productivity but also promote eco-friendliness. A study from the International Journal of Advanced Manufacturing Technology highlights that laser cutting generates up to 80% less waste compared to conventional cutting techniques. Moreover, these machines often utilize clean energy sources, resulting in a substantial decrease in greenhouse gas emissions. As manufacturers increasingly embrace these technologies, the transition towards sustainable production practices becomes more achievable, reflecting a collective commitment to reducing environmental impact in the industrial sector.

The world of manufacturing is experiencing a significant transformation, driven by advancements in technology such as CNC laser cutting machines. These machines have found successful applications across various industries, showcasing their versatility and efficiency. For example, many companies in the automotive sector have successfully utilized CNC laser cutting to streamline their production processes, improving precision while reducing material waste. This not only leads to cost savings but also enhances the overall quality of the products, demonstrating the strategic advantage of adopting innovative manufacturing techniques.

Tips for optimizing your CNC laser cutting process include conducting thorough experiments to determine the best parameters for your specific materials. Implementing a design of experiments approach can help fine-tune settings for factors such as speed, power, and assist gases, ensuring a burr-free cut and high-quality finish. Additionally, keeping abreast of emerging technologies in laser applications can provide insights into further enhancing production efficiency and sustainability.

In other sectors, such as textiles, CNC laser cutting is making strides by enabling intricate designs and patterns while maintaining sustainability practices. Case studies from companies that have integrated these machines emphasize the importance of adaptability and innovation in staying competitive. Investing in the latest laser cutting technology is not merely a trend; it's a strategic move towards elevating global manufacturing standards and fostering growth in various industries.