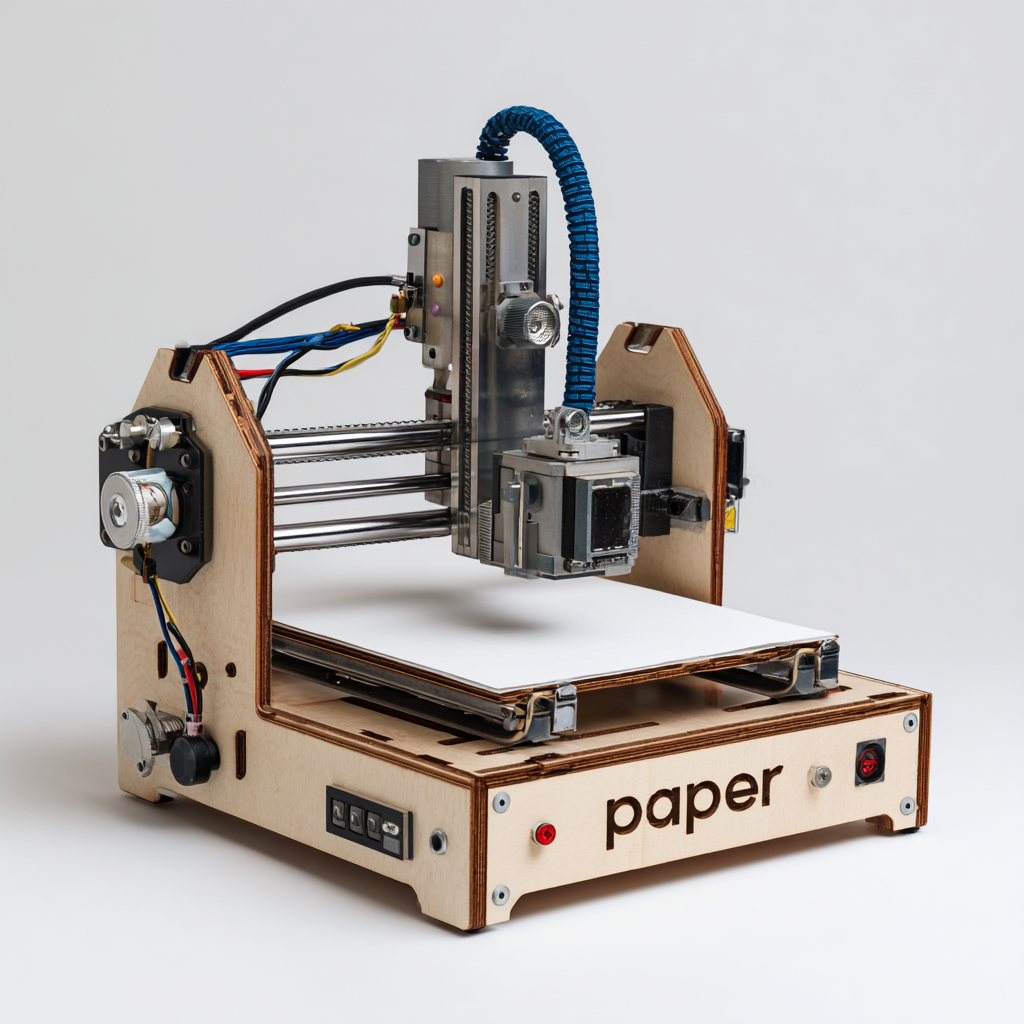

As the demand for precision and efficiency in the manufacturing sector continues to rise, the paper cutting CNC machine has emerged as an essential tool for industries ranging from packaging to print media. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100.78 billion by 2026, with paper cutting applications contributing significantly to this growth. This escalating demand underscores the necessity for businesses to select high-quality manufacturers capable of delivering reliable and innovative solutions. In this ultimate guide, we will delve into the critical considerations for evaluating the best paper cutting CNC machines available, ensuring that your investment aligns with both industrial standards and the specific needs of your operations.

When evaluating the best paper cutting CNC machines, there are several key features that stand out based on industry standards. The first feature to consider is precision. An ideal CNC machine should provide high levels of accuracy in cuts, ensuring that each piece produced meets exact specifications. This is crucial in industries such as packaging and printing where detail matters immensely.

Another significant aspect is the machine’s versatility. Look for models that can handle various types of paper and thicknesses. A versatile machine allows for greater creativity and adaptability, enabling users to execute a wider range of projects without needing multiple machines.

Lastly, ease of use cannot be overlooked. User-friendly interfaces and straightforward programming capabilities make it easier for operators to maximize efficiency and reduce downtime. Investing in advanced software that supports design and modification can also streamline the workflow, allowing users to focus on producing high-quality products with minimal hassle.

Tips to remember: always check for customer reviews and try to see demos of machines whenever possible. Understanding the specific needs of your production line will also aid in making an informed decision.

| Feature | Importance | Industry Standard | Typical Range |

|---|---|---|---|

| Cutting Precision | High | ±0.1 mm | ±0.05 mm - ±0.2 mm |

| Material Compatibility | Medium | Variety of Paper Types | Paper, Cardstock |

| Cutting Speed | High | 200-1000 mm/s | 300 - 800 mm/s |

| Software Compatibility | Medium | CAD/CAM Software | Various Formats Supported |

| Ease of Use | High | User-Friendly Interface | Intuitive Design |

In the realm of CNC paper cutting, precision is not just a desirable feature—it's a necessity. The accuracy of cuts can significantly impact the final product, whether it's for intricate designs or bulk production. Key metrics such as blade sharpness, cutting speed, and machine tolerance play pivotal roles in determining the effectiveness of a CNC machine. For instance, a high-quality CNC machine should maintain precise tolerances, often within a few thousandths of an inch, ensuring that every cut aligns perfectly with the intended design.

Moreover, understanding the importance of measurement in CNC paper cutting extends beyond the machine itself. Factors such as the type of paper being used and the material thickness must be considered, as they can influence the cutting parameters. For instance, thicker materials may require slower cutting speeds and increased blade pressure to achieve a clean cut. Therefore, evaluating potential machines through trials and observing their performance on various materials can highlight their precision capabilities, making the selection process much more informed and effective.

When it comes to finding the best CNC paper cutting machines, a comparative analysis of leading models can provide valuable insights for potential buyers. Recent data from industry reports indicate that the global CNC machine market is projected to grow by over 6% annually through 2026, highlighting a robust demand for high-performance paper cutting technology. Key performance indicators such as cutting speed, precision, and user-friendliness are critical in evaluating these machines. For instance, models like the Zund G3 and the Esko Kongsberg offer impressive cutting speeds of up to 100 meters per minute, significantly enhancing productivity in commercial environments.

User reviews also play a crucial role in assessing the practicality of these machines. According to a survey conducted by Techsci Research, over 75% of users reported that the precision of CNC paper cutters directly impacted their production quality, with many praising the ability to handle intricate designs without compromising accuracy. Notably, customers have highlighted features like adaptive cutting technology in the Roland DG series, which automatically adjusts blade settings based on material thickness, making it a favorite among users. Such insights into performance data and real-world experiences are invaluable for businesses aiming to invest in cutting-edge technology that meets their specific needs.

When evaluating paper cutting CNC machines for commercial use, determining the balance between cost and quality is crucial for achieving a positive return on investment (ROI). Businesses often face the challenge of selecting machinery that not only meets their production needs but also aligns with their budget constraints. It's essential to consider both the initial purchase price and the long-term operational costs, including maintenance, energy consumption, and the skill level required to operate the equipment effectively.

In a market where advancements in technology are rapid, investing in high-quality CNC machines can lead to significant efficiencies. While cheaper options might appear appealing at first glance, they can quickly become a liability if they do not deliver consistent performance or require frequent repairs. To ensure that your investment pays off, it's critical to analyze the reliability of the machine, the manufacturer’s support, and how well the product integrates into your overall manufacturing process. By carefully evaluating these factors, businesses can make informed decisions that enhance productivity and profitability, ultimately setting the stage for long-term success in their operations.

The paper cutting industry is experiencing a significant transformation driven by automation and advancements in CNC (Computer Numerical Control) technology. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117 billion by 2026, with paper cutting machines playing a crucial role in this growth. Automation enables manufacturers to enhance precision and efficiency in cutting processes, leading to reduced waste and increased productivity. As a result, businesses that adopt these advanced paper cutting CNC machines are seeing substantial improvements in operational performance.

Moreover, the integration of artificial intelligence and machine learning into CNC systems is setting new standards in the industry. A study by Research and Markets indicates that smart automation solutions are expected to increase operational efficiency by up to 30% in the next few years. These innovations allow for real-time monitoring and adaptive cutting processes, ensuring that machines can respond swiftly to variations in material thickness and type. As the demand for customized paper products rises, businesses equipped with automated CNC cutting technology are better positioned to meet evolving customer needs while maintaining high-quality standards.