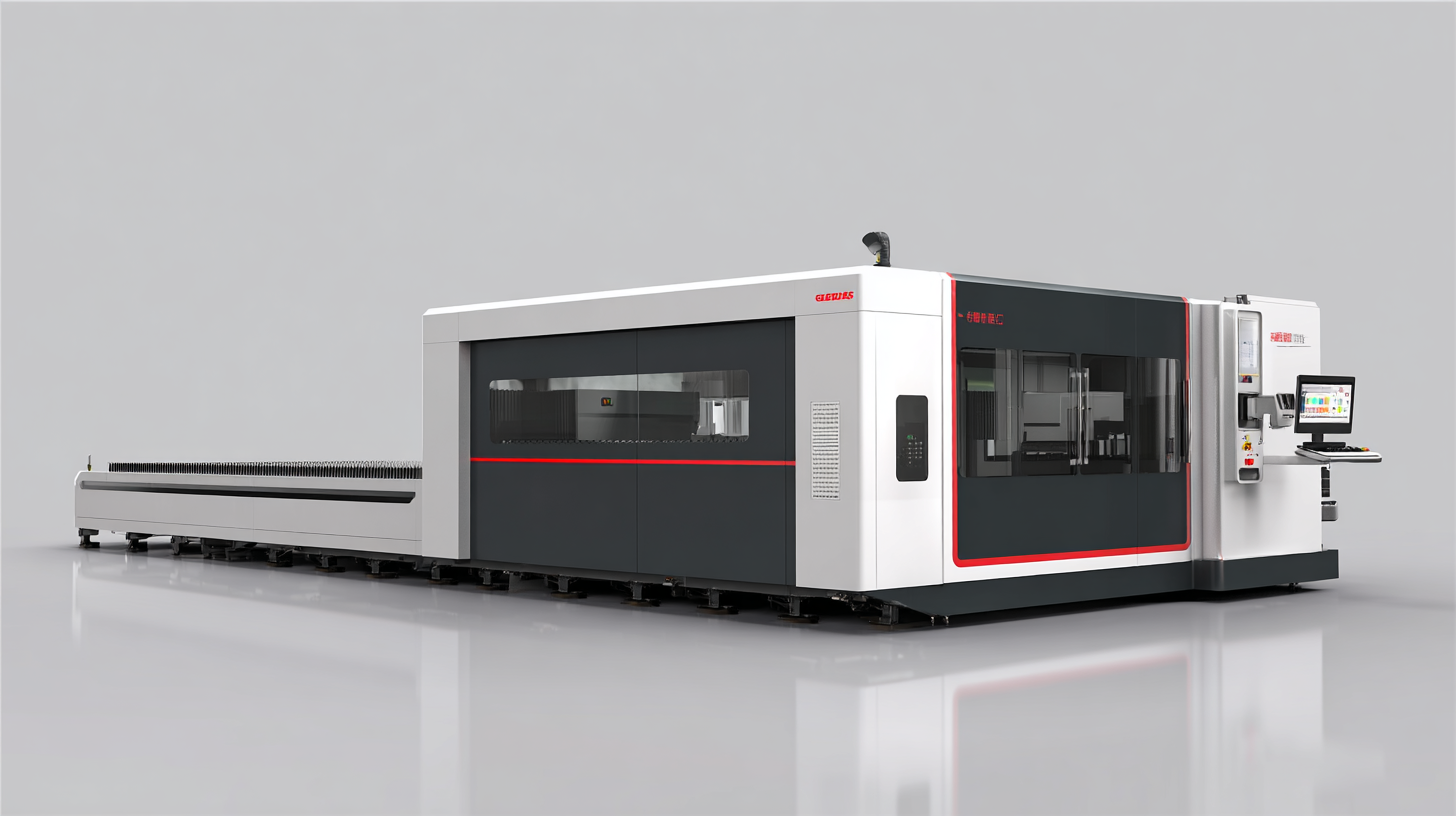

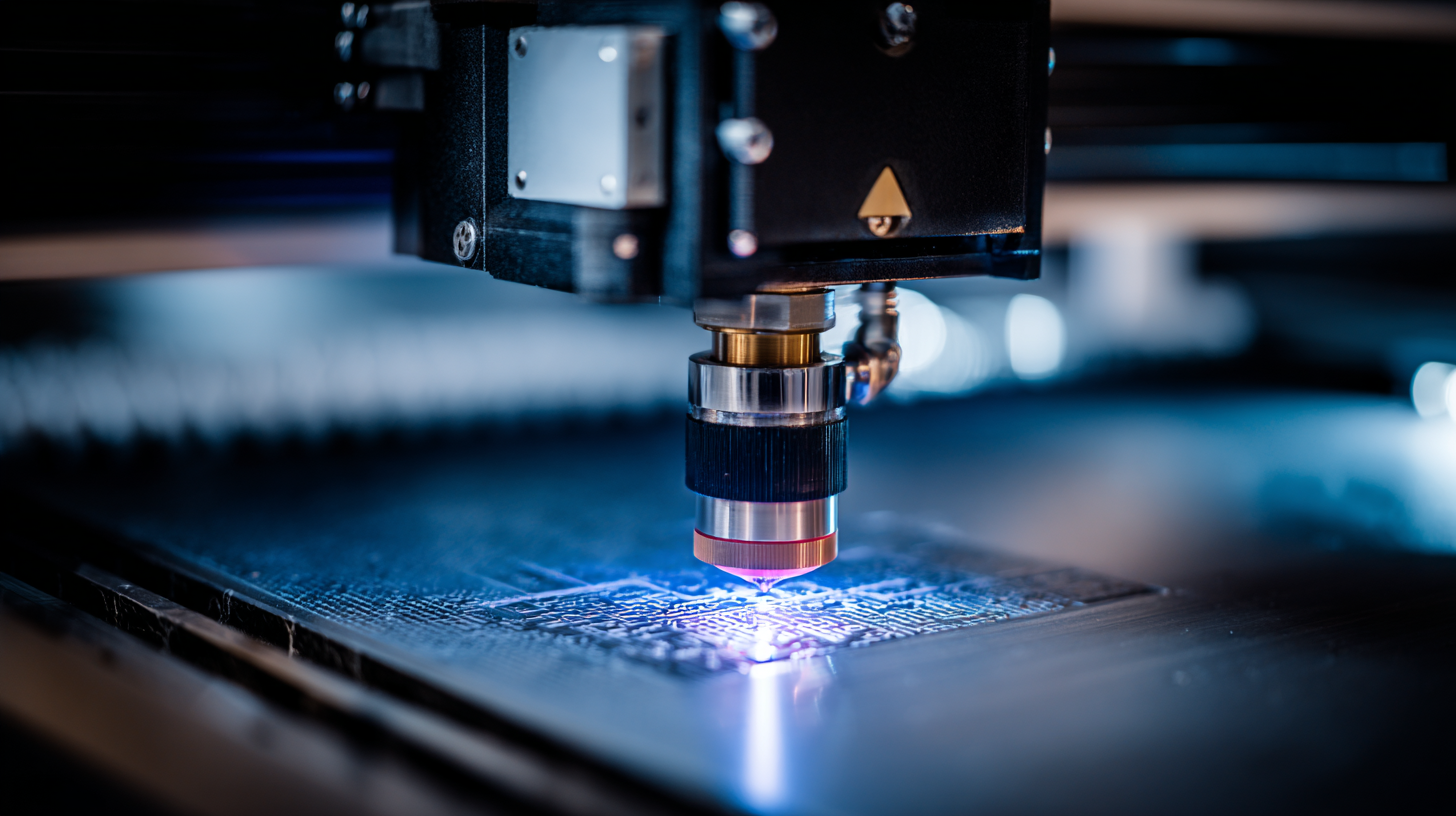

In the realm of modern manufacturing, the evolution of technology has led to the rising prominence of the laser CNC machine, which has proven to be an invaluable asset for precision cutting and engraving across various industries. According to a report by Grand View Research, the global laser cutting market size was valued at USD 3.68 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 6.6% from 2021 to 2028. This surge is attributed to the growing demand for customized and high-precision components in sectors such as automotive, aerospace, and electronics. As businesses continue to strive for efficiency and quality, understanding the best laser CNC machine specifications and setup becomes crucial for manufacturers looking to leverage these technological advancements. In this comprehensive guide, we will explore the essential criteria, features, and optimal configurations that define the leading laser CNC machines, ultimately unlocking enhanced precision and productivity for diverse applications.

In the competitive landscape of laser CNC machines, after-sales service can often be the deciding factor for manufacturers looking for optimal performance and longevity. A study highlighted that businesses adopting a proactive maintenance strategy experience a 25% reduction in downtime, emphasizing the advantages of comprehensive after-sales support. Such services not only ensure the equipment operates at peak efficiency but also extend its lifecycle, which is crucial given the significant investments these machines represent.

To maximize the benefits of after-sales service, companies should consider partnering with providers that offer robust support networks. For instance, rapid response times for technical support, regular maintenance checks, and accessible spare parts can greatly alleviate operational hiccups. Ensuring that technicians are trained to understand specific machine nuances can yield improvements in quality control, akin to those seen in industries that heavily rely on precision, like automotive and aerospace.

Tip: When evaluating laser CNC machine vendors, inquire about the details of their after-sales support. A vendor that provides a transparent service level agreement (SLA) can position you for long-term success by minimizing unexpected disruptions.

Tip: Regularly scheduled training sessions for your team on the latest machine capabilities and maintenance processes can lead to improved usage and reductions in operational errors, ultimately maximizing your investment return.

When investing in a laser CNC machine, understanding maintenance costs is crucial to ensuring long-term operational efficiency. Regular maintenance can help minimize unexpected breakdowns and prolong the life of your equipment. Costs typically include routine check-ups, replacement parts, and potential software upgrades. Depending on the machine's usage and complexity, these expenses can fluctuate significantly.

Tip: Create a maintenance schedule based on manufacturer recommendations and your usage patterns. This proactive approach not only reduces repair costs but also enhances performance over time.

Moreover, consider the availability of parts and service providers when choosing your laser CNC machine. Machines with readily available components might incur lower long-term maintenance costs compared to those with specialized parts.

Tip: Research and connect with local service technicians or companies to understand their pricing structures and response times. Having a reliable service partner can save you both time and money during emergencies. Investing in quality maintenance now can prevent significant expenses down the line, making it a vital aspect of your laser CNC setup.

The increasing demand for precision in manufacturing has propelled the adoption of laser CNC machines across various industries. According to a report by Grand View Research, the global laser cutting machine market size was valued at USD 3.81 billion in 2020 and is expected to expand at a CAGR of 5.5% from 2021 to 2028. This growth highlights the importance of understanding the specifications and setup of these machines to fully realize their capabilities. By examining real-world applications, we can see how industries effectively utilize laser CNC technology to enhance productivity and precision.

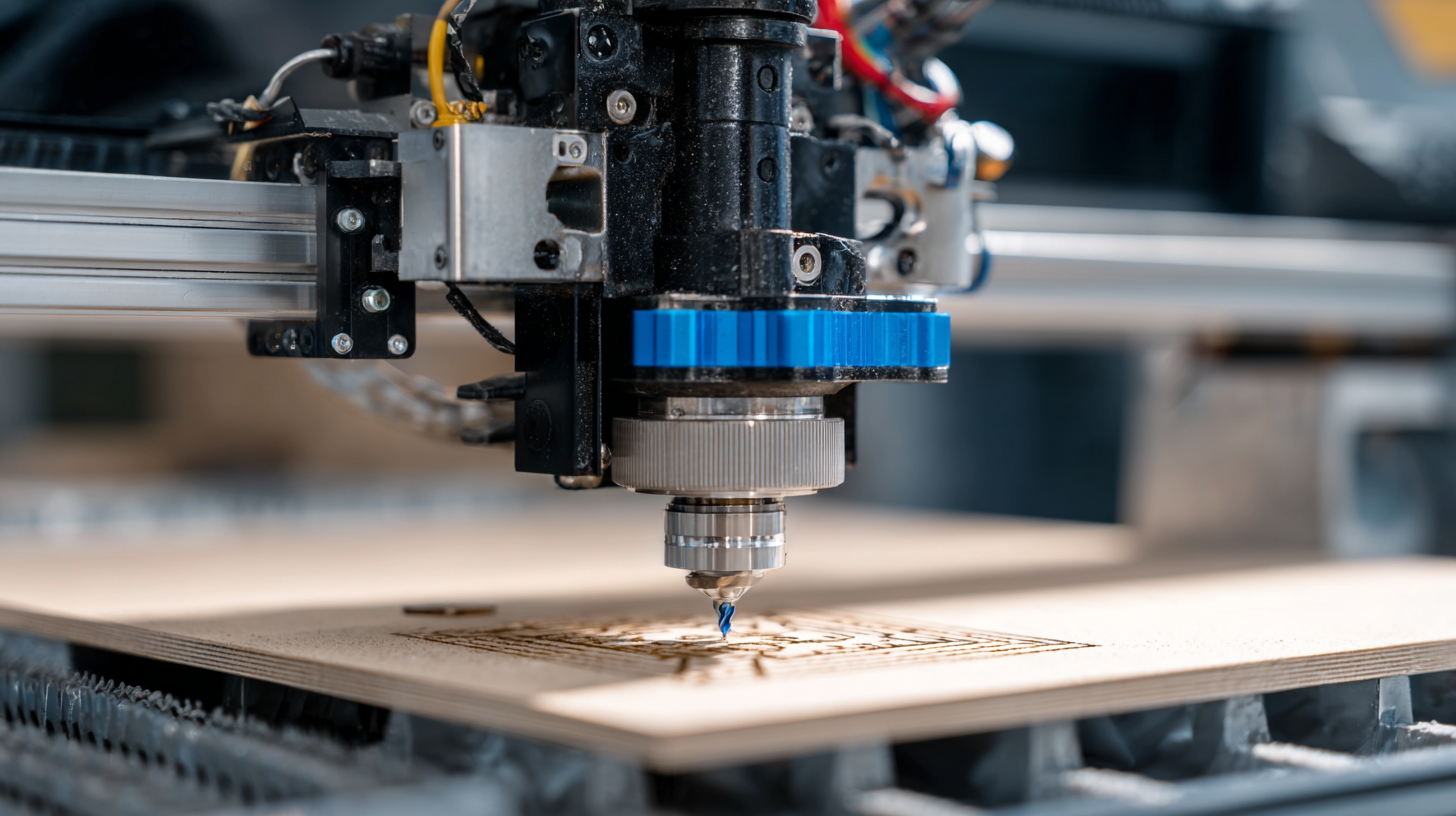

One notable example is the aerospace sector, where companies like Boeing have integrated laser CNC machines for intricate part fabrication. A case study by the National Center for Advanced Technologies found that using laser cutting technology improved accuracy by 50% compared to traditional methods, significantly reducing material waste. Furthermore, a 2021 study published in the Journal of Manufacturing Processes indicated that the setup of a laser CNC machine, when optimized, can decrease cycle times by as much as 30%. These examples illustrate the profound impact of laser CNC machines in achieving operational excellence and meeting the high standards required in competitive industries.

When selecting a laser CNC machine, the importance of after-sales services cannot be overstated. Comprehensive support is crucial for maintaining production efficiency and ensuring that businesses can capitalize on their investments. Key features to consider include 24/7 customer support, the availability of replacement parts, and the provision of skilled technicians for on-site assistance. A robust after-sales service guarantees not only prompt troubleshooting but also regular maintenance, which can significantly prolong the life of the machine.

Moreover, effective training programs should be an integral part of the after-sales package. As technology evolves, ensuring that your team is up to date with the latest operational protocols is essential. This not only enhances productivity but also fosters a more profound understanding of the machinery’s capabilities. By prioritizing after-sales services, businesses can create a more resilient operational framework, capable of adapting to changes and challenges in the ever-competitive manufacturing landscape.

When considering the investment in a laser CNC machine, balancing the initial purchase price against long-term maintenance expenses is crucial for any business looking to optimize its operations. According to a report by Market Research Future, the laser engraving machine market is projected to grow at a CAGR of 6.7% from 2020 to 2027, highlighting a trend towards increasing reliance on technology that balances efficiency with cost-effectiveness. Investing in a machine that may have a higher upfront cost but offers lower maintenance can lead to greater profitability in the long run.

When considering the investment in a laser CNC machine, balancing the initial purchase price against long-term maintenance expenses is crucial for any business looking to optimize its operations. According to a report by Market Research Future, the laser engraving machine market is projected to grow at a CAGR of 6.7% from 2020 to 2027, highlighting a trend towards increasing reliance on technology that balances efficiency with cost-effectiveness. Investing in a machine that may have a higher upfront cost but offers lower maintenance can lead to greater profitability in the long run.

Tip: Before purchasing, assess the total cost of ownership. This includes not just the initial price of the laser CNC machine, but also parts, labor, and potential downtime costs associated with maintenance. A laser CNC machine that costs more initially may save significant amounts through reduced maintenance frequency and part replacement.

Additionally, regular maintenance can extend the life of your equipment and improve performance. Data from industry reports indicates that organizations implementing preventative maintenance strategies can reduce equipment failure rates by up to 40%. Therefore, choosing a machine with accessible and affordable maintenance can provide peace of mind and enhance overall operational efficiency.

Tip: Negotiate maintenance contracts and warranties when purchasing your laser CNC machine. Ensure that they cover critical components and offer quick service response times to minimize downtime and maintain productivity.