In 2023, the manufacturing landscape continues to evolve, with the demand for precision and efficiency driving the adoption of advanced technologies. One pivotal innovation in this arena is the CNC machine laser cutting machine, which has revolutionized how industries approach metal fabrication and precise cutting tasks. According to a recent market research report by XYZ Analytics, the global CNC laser cutting machine market size is projected to reach $7.02 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.1% from 2021 to 2026. This surge is attributed to the increasing need for customized, high-quality outputs in sectors ranging from automotive to aerospace. As businesses seek to stay competitive, understanding the intricacies of selecting the right CNC machine laser cutting machine becomes essential, ensuring not only operational efficiency but also alignment with industry standards and customer expectations.

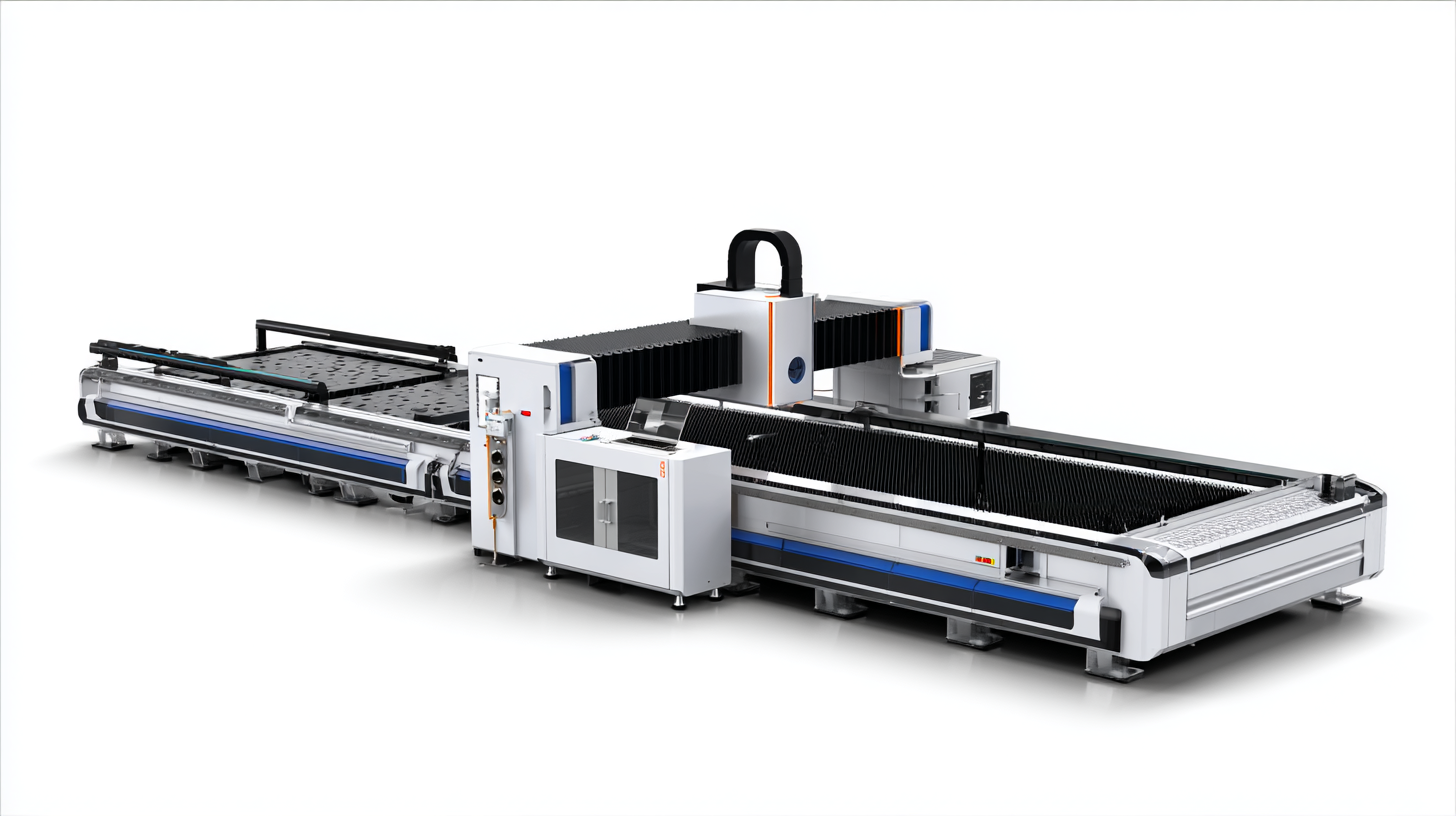

CNC laser cutting machines have revolutionized the manufacturing landscape, providing precision and efficiency that traditional cutting methods struggle to match. Understanding the components and functions of these machines is crucial for anyone looking to invest in one. Typically, a CNC laser cutter consists of a laser source, a CNC controller, and a mechanical system that facilitates movement. The laser source generates a focused beam of light that can cut through various materials, while the CNC controller interprets design files and commands the mechanical components to execute exact cuts.

A key aspect of CNC laser cutting technology is its versatility. These machines can handle a wide range of materials, including metals, plastics, and wood. The ability to program intricate designs ensures that businesses can achieve complex cuts with just a few clicks. Furthermore, the advancements in laser technology, including fiber lasers, have improved speed and reduced energy consumption, making these machines not only cost-effective but also environmentally friendly. As you explore options for a CNC laser cutting machine in 2023, understanding these essential features will help you make an informed decision that aligns with your production needs.

When selecting a CNC laser cutting machine, several key factors should be prioritized to ensure efficiency and precision. First and foremost, consider the material compatibility of the machine. Different laser cutting machines are designed to handle various materials, such as metals, plastics, and wood. Understanding the specific materials you plan to work with will allow you to choose a machine that delivers optimal performance and cutting quality.

Another crucial factor is the power and speed of the laser. Higher wattage options provide faster cutting capabilities and the ability to work with thicker materials. However, balance is essential; a machine that is too powerful for your needs can lead to increased operational costs. Additionally, examine the software compatibility and ease of use. An intuitive software interface can significantly streamline your workflow, allowing you to focus on creativity and productivity instead of troubleshooting technical issues. By carefully considering these factors, you'll be better equipped to identify the CNC laser cutting machine that best suits your specific requirements in 2023.

In 2023, the landscape of CNC laser cutting technology continues to evolve, driven by advancements that cater to various industries including automotive, aerospace, and electronics. The market for CNC machines is expected to grow significantly, with projections indicating a rise from $101.22 billion in 2025 to approximately $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. This robust growth is indicative of an increasing demand for precision cutting and fabrication processes across multiple sectors.

Different types of CNC laser cutting technologies play a crucial role in this market expansion. Fiber lasers, CO2 lasers, and solid-state lasers each offer unique benefits tailored to specific applications. For instance, fiber lasers are particularly favored for their efficiency and versatility in cutting thin to medium materials, making them suitable for the electronics industry. Meanwhile, CO2 lasers are widely utilized in cutting non-metal materials, including plastics and wood, which find applications in the automotive sector. Understanding these technologies and their functions is essential for businesses aiming to invest in the right equipment for their operational needs.

When selecting a CNC laser cutting machine in 2023, understanding industry certifications is crucial. Certifications not only indicate compliance with safety and quality standards but also ensure that your machine operates efficiently and safely within various industrial regulations. Pay close attention to certifications like ISO 9001 or CE marking, as these validate the manufacturer’s commitment to quality management and safety. This knowledge can significantly influence your purchasing decision and long-term satisfaction.

One key tip is to ensure the machine you choose aligns with your specific industry requirements. For example, different industries may have unique certifications that apply to CNC machines, depending on the materials used and the types of cutting processes involved. Research the certifications relevant to your sector to streamline your decision-making process and avoid potential compliance issues down the line.

Additionally, when comparing machines, verify the documentation for each model’s certification status. Ask the manufacturer to provide clear proof of compliance. If a machine lacks proper certification, it may not only be a risk to your operations but could also lead to costly downtime or legal complications. Prioritizing certified machines can safeguard your investment and ensure optimal performance.

Setting up your CNC laser cutting machine doesn’t have to be a daunting task. The first step is to ensure you have the right workspace. Clear out any clutter and set up a dedicated area that is well-ventilated and spacious enough to accommodate both the machine and your materials. This will not only enhance your efficiency but also ensure safety during operation.

Next, carefully read the manufacturer's instructions for assembly and installation. Each machine is different, so familiarize yourself with its components, and don't skip any setup steps. It's crucial to check wiring and connections to prevent issues down the line. Remember, proper calibration of the machine is essential for achieving precise cuts and avoiding material waste.

One of the best tips when beginning to use your CNC laser cutter is to practice safe operation. Always wear appropriate protective gear, such as goggles and gloves, and ensure that everyone in the vicinity understands the safety protocols. This not only protects you but also extends the longevity of your equipment by minimizing the risk of errors during operation. By following these steps, you’re setting the stage for successful laser cutting projects ahead.